Coffee a la mode的問題,透過圖書和論文來找解法和答案更準確安心。 我們找到下列懶人包和總整理

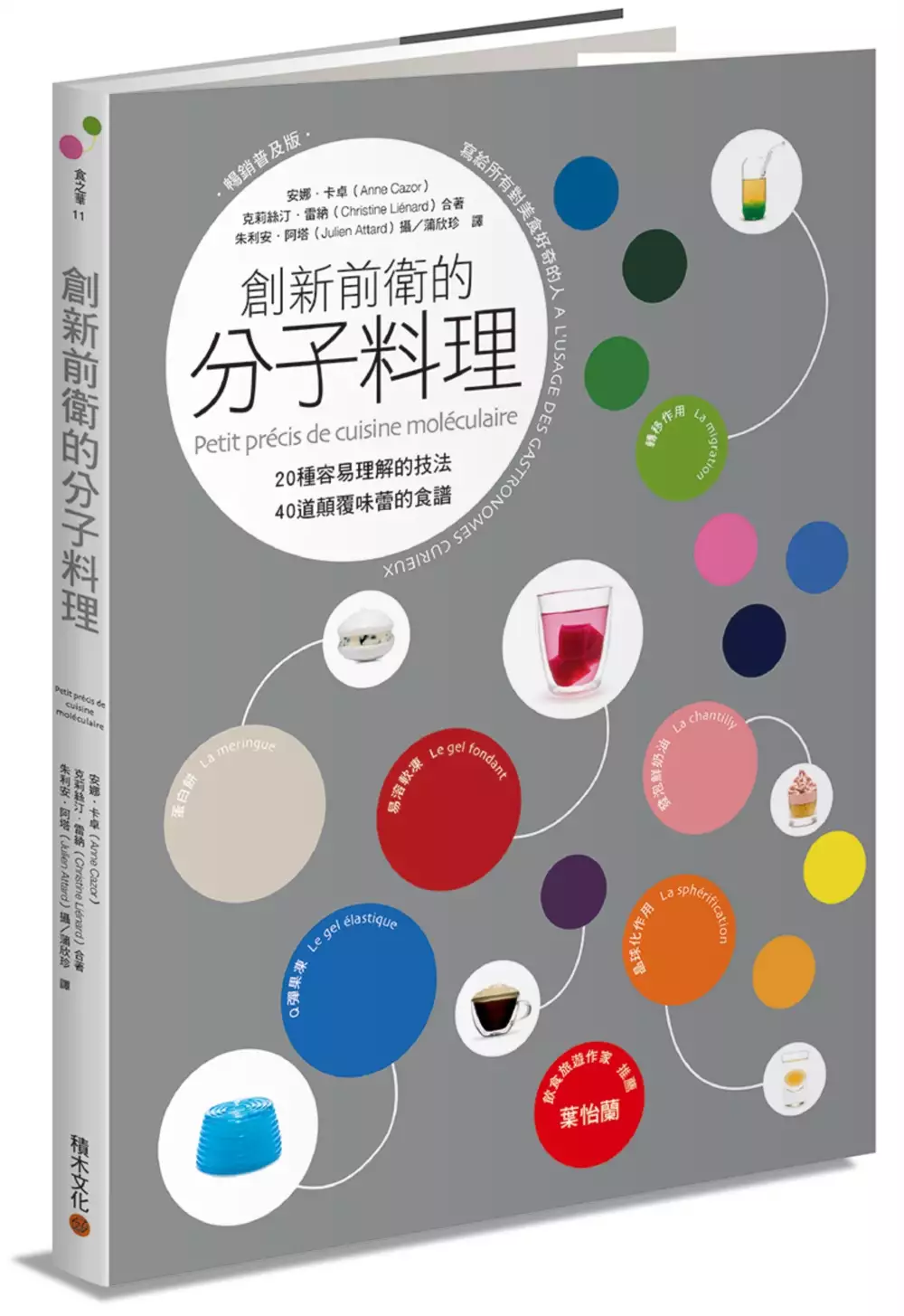

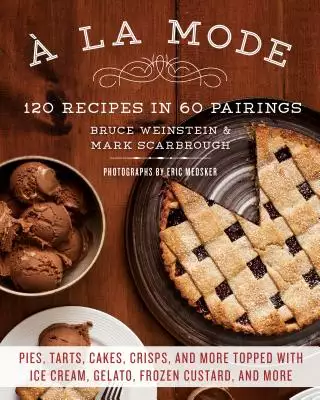

Coffee a la mode的問題,我們搜遍了碩博士論文和台灣出版的書籍,推薦ANNECAZOR寫的 創新前衛的分子料理:20種容易理解的技法.40道顛覆味蕾的食譜(暢銷普及版) 和Scarbrough, Mark/ Weinstein, Bruce的 A La Mode: 120 Recipes in 60 Pairings: Pies, Tarts, Cakes, Crisps, and More Topped With Ice Cream, Gelato, Frozen Custard, and M都 可以從中找到所需的評價。

另外網站[邀約]師大‧Cafe a la mode‧聚餐的好地方!招牌法式布丁吐司好好 ...也說明:cafe à la mode 地址:台北市大安區雲和街2-1號電話:02-2362-3957 營業時間:星期一~五10:00am~10:00pm.

這兩本書分別來自積木文化 和所出版 。

長庚大學 電子工程學系 賴朝松所指導 Mamina Sahoo的 基於石墨烯及生物碳基材料的可撓式電晶體應用與能量攫取 (2021),提出Coffee a la mode關鍵因素是什麼,來自於石墨烯、氟化石墨烯、太阳能电池、摩擦纳米发电机、生物碳、能量收集器。

而第二篇論文國立成功大學 建築學系 潘振宇所指導 吳伊証的 高齡日間照顧中心異味樣態調查與新式自然通風效益評估 (2021),提出因為有 異味、日間照顧中心、自然通風、高齡福祉、室內空氣品質的重點而找出了 Coffee a la mode的解答。

最後網站Café à la Mode - Foursquare則補充:Read 8 tips and reviews from 214 visitors about lively, healthy food and cozy. "Great service!"

創新前衛的分子料理:20種容易理解的技法.40道顛覆味蕾的食譜(暢銷普及版)

為了解決Coffee a la mode 的問題,作者ANNECAZOR 這樣論述:

分子料理其實一點也不難! 一本掌握關於分子料理的各種原理與活用方式 「科學引領我們探索這個大千世界,研究各種自然現象所引發的不同機制反應,而分子廚藝(Gastronomie Moléculaire)這門學問,即在探究烹飪過程所產生的各種變化,以及人們飲食感官上的普遍現象。這門學問也可以稱作食品科學。技術運用科學知識,提供實務上可行的操作方法。在廚藝相關領域中,烹調技術乃應用分子廚藝及各種食品科學的知識,提出新式的操作方法。廚藝融合了藝術和技術,與味道、產品的品質及廚師的能力皆密不可分;操作和理解實乃一體之兩面,這就是所謂的『分子料理』(Cuisine Moléculaire)。這種料理應

用了廚藝中原有的技巧而創造出新的菜色、新的口感、新的風味、新的感受⋯⋯」——摘自本書p.3簡介 ★寫給所有對美食好奇的人 將食材分子重組變化成形形色色的驚奇創意料理, 輕鬆成為廚房裡的魔法師 所有烹調技法都涵蓋科學原理的簡易說明,搭配簡單有趣、創意十足的料理食譜&精美圖片 像是會在嘴裡迸開的巧克力、甜中帶鹹的蔬菜焦糖、晶瑩剔透的蜂蜜珍珠、口感豐潤的黃瓜優格球、未曾聽聞的醬油泡沫慕斯......甚至,越式湯麵竟成了高湯凍,甜心蛋也能變化成方形或管狀!作法簡單,樣貌驚奇,風味多變,顛覆了我們對廚藝和食材的認知與想像,令人大呼過癮! 本書作者Anne Cazor為「分子廚藝」研究領域的博

士,同時也是「創新料理」(Cuisine Innovation)網站(www.cuisine-innovation.fr)的創辦人。她將這本食譜獻給所有喜愛美食的人,包括業餘老饕和專業廚師。書中針對每道分子料理的烹飪技法,提供相關科學原理的簡易說明,同時搭配兩道讀者可以實地運用、快速上手的食譜,簡單有趣、創意十足,佐以大量精美的圖片,帶給讀者無限的想像空間和前所未有的驚喜。

Coffee a la mode進入發燒排行的影片

7 Eleven Foods Spaghetti Bolognese(meat sauce pasta) and Pudding à la mode. I like 711 meat sauce pasta, so I want to keep it forever!? The Pudding à la mode is classic style,like a old fashioned coffee shop menu.

#japanesestuffchannel, #711food, #pasta

基於石墨烯及生物碳基材料的可撓式電晶體應用與能量攫取

為了解決Coffee a la mode 的問題,作者Mamina Sahoo 這樣論述:

Table of ContentsAbstract.......................................................................................................iFigure Captions........................................................................................xiTable Captions...................................................

....................................xxiChapter 1: Introduction1.1 Flexible electronics................................................................................11.2 Graphene the magical material ………………………….……….......21.2.1 Synthesis of graphene…………………………….….…...21.2.1.1 Mechanical exfoliati

on of graphene………………...……21.2.1.2 Epitaxial growth on Sic substrate………………….…..31.2.1.3 Chemical vapor deposition (CVD) method………….…..41.2.2 Graphene transfer…………………………………………....41.3 Application of graphene based Electronics……………………….......51.3.1 Graphene based flexible transparent electrode

……………….61.3.2 Top gated Graphene field effect transistor…………………….71.4 Challenges of flexible graphene based field effect transistors.……….91.5 Energy harvesting devices for flexible electronics………….........….91.6 Solar cell…………………………………………………………...101.6.1 Device architecture…………………………………………101.

6.2 Issues and Challenges of Perovskite solar cells………...121.7 Triboelectric nanogenerator (TENG)………………………………121.7.1 Working mode of TENG………………………………….141.8 Applications of TENG………………………………………………151.8.1 Applications of graphene based TENG…………………....151.8.2 Applications of bio-waste material ba

sed TENG………….171.9 Key challenges of triboelectric nanogenerator…………………....…191.10 Objective and scope of this study………………………………....19Chapter 2: Flexible graphene field effect transistor with fluorinated graphene as gate dielectric2.1 Introduction………………………………………………………....212.2 Material preparation a

nd Device fabrication………………. 232.2.1CVD Growth of Graphene on Copper Foil………………….232.2.2 Transfer of graphene over PET substrate……………...........252.2.3 Fabrication of fluorinated graphene ……………...........252.2.4 F-GFETs with FG as gate dielectric device fabrication……262.2.5 Material and electrical C

haracterization …………………272.3 Results and discussion…………………………………………….282.3.1 Material characterization of PG and FG……………...…...….282.3.2 Electrical characterization of F-GFET with FG as dielectrics..332.3.3 Mechanical stability test of F-GFET with FG as dielectrics ….362.4 Summary…………………………………………………

………....40Chapter 3: Robust sandwiched fluorinated graphene for highly reliable flexible electronics3.1 Introduction………………………………………………………….423.2 Material preparation and Device fabrication ………………….........443.2.1 CVD Growth of Graphene on Copper Foil…………………...443.2.2 Graphene fluorination …...…….…………

…………..............443.2.3 F-GFETs with sandwiched FG device fabrication....................443.2.4 Material and electrical Characterization…..............................453.3 Results and discussion ……………………………………...............453.3.1 Material characterization of sandwiched…………………….453.3.2 Electric

al characterization of F-GFET with sandwiched FG....473.3.3 Mechanical stability test of F-GFET with sandwiched FG…503.3.4 Strain transfer mechanism of sandwiched FG………………513.4 Summary…………………………………………………………....53Chapter 4: Functionalized fluorinated graphene as a novel hole transporting layer for ef

ficient inverted perovskite solar cells4.1 Introduction………………………………………………………….544.2 Material preparation and Device fabrication......................................564.2.1 Materials ………………………...…………………………564.2.2 CVD-Graphene growth ……………………………...…...564.2.3 Graphene fluorination …………………………………….564.

2.4 Transfer of fluorinated graphene…………………………...574.2.5 Device fabrication …………………………………….….574.2.6 Material and electrical Characterization …….....................584.3 Results and discussion …………………………………………….594.3.1 Surface electronic and optical properties of FGr……….….594.3.2 Characterization o

f FGr and perovskite surface ……….…644.3.3 Electrical performance of PSC………………….…….…...694.3.4 Electrical performance of Flexible PSC……………………724.4 Summary…………………………………………………………...78Chapter 5: Flexible layered-graphene charge modulation for highly stable triboelectric nanogenerator5.1 Introduction…………

…………………………………………....795.2 Experimental Section……………………………………………….825.2.1 Large-area graphene growth ……………………………….825.2.2 Fabrication of Al2O3 as the CTL …………………………...825.2.3 Fabrication of a Gr-TENG with Al2O3 as the CTL………825.2.4 Material characterization and electrical measurements…….835.3 Results

and discussion.…………………………………...…………845.3.1 Material Characterization of Graphene Layers/Al2O3……845.3.2 Working Mechanism of Gr-TENG with Al2O3 as CTL…915.3.3 Electrical Characterization of Gr-TENG with Al2O3 CTL…945.3.4 Applications of the Gr-TENG with Al2O3 as CTL……….1015.4 Summary…………………………………………

……………….103Chapter 6: Eco-friendly Spent coffee ground bio-TENG for high performance flexible energy harvester6.1 Introduction…………………………………………………….......1046.2 Experimental Section…………………………………………….1086.2.1 Material Preparation …………………………………….1086.2.2 Fabrication of SCG powder based TENG………………...1086

.2.3 Fabrication of SCG thin-film based TENG ………………1096.2.4 Material characterization and electrical measurements….1106.3 Results and discussion.…………………………………...………1116.3.1 Material Characterization of SCG powder and thin film….1116.3.2 Working Mechanism of SCG-TENG……………………...1186.3.3 Electrical Cha

racterization of SCG-TENG……………….1226.3.4 Applications of the SCG thin-film based TENG………….1326.4 Summary………………………………………………………….134Chapter 7: Conclusions and future perspectives7.1 Conclusion………………………………………………………....1357.2 Future work …………………………….………………………….1377.2.1 Overview of flexible fluorinated g

raphene TENG..............1377.2.1.1 Initial results………………………………….…1387.2.2.1.1 Fabrication of FG-TENG………………1387.2.2.1.2 Working principle of FG-TENG……….1397.2.2.1.3 Electrical output of FG-TENG.………...140References…………………………………………………………….142Appendix A: List of publications………………….……………..........177A

ppendix B: Fabrication process of GFETs with fluorinated graphene (FG) as gate dielectric……........……………………………………….179Appendix C: Fabrication process of GFETs with sandwiched FG…....180Appendix D: Fabrication process of inverted perovskite solar cell with FGr as HTL…………………………………………………………….181Appendi

x E: Fabrication of a Gr-TENG with Al2O3 as the CTL…….182Appendix F: Fabrication of SCG based triboelectric nanogenerator….183Figure captionsFigure 1-1 Exfoliated graphene on SiO2/Si wafer……………………….3Figure 1-2 Epitaxial graphene growth on SiC substrate………………....3Figure 1-3 Growth mechanism of graphe

ne on Cu foil by CVD ……......4Figure 1-4 Wet transfer process of CVD grown graphene…………...….5Figure 1-5 RGO/PET based electrodes as a flexible touch screen.……....6Figure 1-6 Graphene based (a) touch panel (b) touch-screen phone…….7Figure 1-7 Flexible graphene transistors (a) (Top) Optical photograph

of an array of flexible, self-aligned GFETs on PET. (Bottom) The corresponding schematic shows a device layout. (b) Schematic cross-sectional and top views of top-gated graphene flake–based gigahertz transistors. (Left) AFM image of a graphene flake. (Right) Photograph of flexible graphene devices

fabricated on a PI substrate. (c) Cross-sectional schematic of flexible GFETs fabricated using a self-aligned process……8Figure 1-8 The magnitude of power needed for meet certain operation depending critically on the scale and applications………………………10Figure 1-9 Schematic diagrams of PSC in the (a) n-i

-p mesoscopic, (b) n-i-p planar, (c) p-i-n planar, and (d) p-i-n mesoscopic structures………...12Figure 1-10 Schematic illustration of the first TENG...………………...13Figure 1-11 Working modes of the TENG. (a) The vertical contact-separation mode. (b) The lateral sliding mode. (c) The single-electrode mode

. (d) The free-standing mode ………………………………...……14Figure 1-12 Schematic illustration of (a) device fabrication of graphene-based TENGs (b) graphene/EVA/PET-based triboelectric nanogenerators (c) device fabrication of stretchable CG based TENG with electrical output performance……………………………………………………...17

Figure 1-13 Schematic illustration and output performance of bio-waste material based TENG (a) Rice-husk (b) Tea leaves (c) Sun flower powder (SFP) (d) Wheat stalk based TENG………….…………………………18Figure 2-1 Graphene synthesis by LPCVD method……….…………...24Figure 2-2 Schematic diagram of (a) preparation pro

cess of 1L-FG/copper foil (b) Layer by layer assembly method was used for fabricating three-layer graphene over copper foil and then CF4 plasma treatment from top side to form 3L-FG/copper foil…………………….26Figure 2-3 Schematic illustration of fabrication process of F-GFET with FG as gate dielectric ……

……………………………………………….27Figure 2-4 (a) Raman spectra of PG, 1L-FG and 3L-FG after 30 min of CF4 plasma treatment over copper foil. (b) Peak intensities ratio ID/IG and optical transmittance of PG, 1L-FG and 3L-FG. Inset: image of PG and 1L-FG film over PET substrate. (c) Typical Raman spectra of PG, 1L

-FG and 3L-FG on PET substrate. (d) Optical transmittance of PG, 1L-FG and 3L-FG film over PET substrate. The inset shows the optical image of GFETs with FG as gate dielectrics on PET ……….…………30Figure 2-5 XPS analysis result of (a) PG (b) 1L-FG (c) 3L-FG where the C1s core level and several carbon f

luorine components are labeled. The inset shows the fluorine peak (F 1s) at 688.5 eV……………………….32Figure 2-6 (a) Water contact angle of PG, 1L-FG and 3L-FG over PET substrate. (b) The relationship between water contact angle of PG, 1L-FG and 3L-FG and surface-roughness………………………………………33Figure 2-7 (a) I

d vs. Vd of w/o-FG, w/1L-FG and w/3L-FG samples after 30 min of CF4 plasma (b) Id vs. Vg of w/o-FG, w/1L-FG and w/3L-FG samples at a fixed value of drain to source voltage, Vds of 0.5 V (c) Gate capacitance of w/o-FG, w/1L-FG and w/3L-FG samples (d) Gate leakage current of w/o-FG (naturally formed A

l2OX as gate dielectric), w/1L-FG and w/3L-FG samples ……………………………...…………...……...34Figure 2-8 (a) Schematic illustration of bending measurement setup at different bending radius. (i) Device measurement at (i) flat condition (ii) bending radius of 10 mm (iii) 8 mm (iv) 6 mm. Inset shows the photograph

of measurement setup. Change in (b) carrier mobility (c) ION of w/o-FG, w/1L-FG and w/3L-FG samples as a function of bending radius. The symbol ∞ represents the flat condition. Change in (d) carrier mobility (e) ION of w/o-FG, w/1L-FG and w/3L-FG samples as a function of bending cycles (Strain = 1.

56%)…………………………………….38Figure 3-1 Schematic illustration of the flexible top gate graphene field effect transistor with sandwich fluorinated graphene (FG as gate dielectric and substrate passivation layer) ……………………………...…………44Figure 3-2 Raman spectra of (a) PG/PET and PG/FG/PET substrate (b) sandwiche

d FG (FG/PG/FG/PET). Inset showing the optical transmittance of sandwiched FG. (c) HRTEM image for 1L-FG.……………….….…46Figure 3-3 (a) Id vs. Vd of FG/PG/FG device at variable vg (−2 to 2 V). (b) Id vs. Vg of FG/PG/FG. (c) Gate capacitance of FG/PG/FG ….…….48Figure 3-4 Raman spectra of devices under be

nding (a) PG/PET (Inset shows the 2D peak) (b) PG/FG/PET (inset shows the 2D peak) …….…49Figure 3-5 (a) Change in Mobility (b) change in ION of PG/PET and PG/FG/PET as a function of bending radius between bending radii of ∞ to 1.6 mm in tensile mode (c) Change in Mobility (d) Change in ION of PG/PET

and PG/FG/PET as a function of bending cycles. Inset of (c) shows the photograph of F-GFETs with sandwich FG on the PET substrate (e) change in resistance of w/1L-FG, 1L-FG/PG/1L-FG samples as a function of bending radius ………………………...……………….50Figure 3-6 Schematic evolution of proposed strain transf

er mechanism through PG/PET and PG/FG/PET. The inset of PG/PET sample shows the generation of sliding charge due to interfacial sliding between PG and PET ………………………………………………………………….….52Figure 4-1 FGr fabrication and transfer process …………….………....57Figure 4-2 (a) Raman analysis of pristine graphene a

nd the FGr samples after 5, 10, 20, and 30 min of CF4 plasma treatment over Cu foil (b) Raman intensity ratios (I2D/IG and ID/IG) of fluorinated graphene, with respect to the exposure time ……………………………………………60Figure 4-3 SEM images of (a) ITO, (b) ITO/1L-FGr, (c) ITO/2L-FGr, and (d) ITO/3L-FGr …………………

………………………………….61Figure 4-4 XPS analysis of FGr with (a) 5 min (b) 10 min and (c) 20 min of CF4 plasma treatment on the Cu foil (d) The fluorine peak (F1s) of FGr (f) The correlation of the carbon-to-fluorine fraction (C/F) with exposure time and the corresponding carrier concentrations …………….………62Fi

gure 4-5 Tauc plots and UV–Vis absorption spectra of FGr films with CF4 plasma treatment for (a) 5, (b) 10, and (c) 20 min ….………......….63Figure 4-6 WCAs on PEDOT: PSS and 1L, 2L, and 3L FGr samples ...64Figure 4-7 (a) Mechanism of large grain growth of perovskite on a non-wetting surface (b) Top-vi

ew and cross-sectional surface morphologies of perovskites on various HTLs ………………………………...…………65Figure 4-8 XRD of perovskite films on various HTL substrates ….…...66Figure 4-9 UPS spectra of various numbers of FGr layers on ITO: (a) cut-off and (b) valance band spectra …………………………………….….67Figure 4-10

Energy band diagrams of PSCs with (a) PEDOT: PSS, (b) 1L-FGr, (c) 2L-FGr, and (d) 3L-FGr as HTL …………………….…….68Figure 4-11 (a) Steady state PL spectra of PEDOT: PSS/perovskite and FGr/perovskite films. (b) TRPL spectral decay of PEDOT: PSS/perovskite and FGr/perovskite films………………………….……69Figure 4-1

2 (a) Schematic representation of a PSC having an inverted device configuration. (b) Cross-sectional HRTEM image of the ITO/ FGr–perovskite interface………………………………………...………70Figure 4-13 Photovoltaic parameters of PSCs incorporating various HTL substrates: (a) PCE (%), (b) Voc (V), (c) Jsc (mA/cm2), an

d (d) FF (%)....71Figure 4-14 Normalized PCEs of target and control PSCs incorporating various HTL substrates, measured in a N2-filled glove box. (a) Thermal stability at 60 °C (b) Light soaking effect under 1 Sun (c) Stability after several days …………………………………………………………….72Figure 4-15 (a) Schematic r

epresentation of the structure of a flexible PSC on a PET substrate (b) J–V curves of control and target flexible PSCs, measured under both forward and reverse biases. (c) Average PCE of flexible PSCs incorporating PEDOT: PSS and FGr HTLs……….…73Figure 4-16 (a) Normalized averaged PCEs of the flexibl

e PSCs after bending for 10 cycles at various bending radii. (b) Normalized averaged PCEs of the flexible PSCs plotted with respect to the number of bending cycles at a radius of 6 mm ………………………………………………75Figure 4-17 Photovoltaics parameters of flexible PSCs with various HTL substrates: (a) JSC (mA/c

m2), (b) Voc (V), and (c) FF (%) ……………....75Figure 4-18 XRD patterns of perovskite films on PET/ITO/FGr, recorded before and after bending 500 times …………………………………….76Figure 4-19 SEM images of (a) perovskite films/FGr/ITO/PET before bending (b) after bending 500 times (c) perovskite films/PEDOT: PSS/

ITO/PET before bending (d) after bending 500 times ……………….…77Figure 4-20 PL spectra of perovskite films on PET/ITO/FGr, recorded before and after various bending cycles …………………………….…78Figure 5-1 Schematic illustration showing the fabrication process of a flexible Gr-TENG with Al2O3 as the CTL ……………

………………...83Figure 5-2 The Raman spectra of (a) graphene/Al-foil/PET and (b) graphene/Al2O3/Al-foil/PET. The I2D/IG of graphene layers (1L, 3L and 5L) over (c) Al-foil/PET substrate (d) Al2O3/Al-foil/PET substrate …...85Figure 5-3 XRD patterns of (a) graphene/Al-foil/PET and (b) graphene/Al2O3/Al-foi

l/PET ……………………………………………86Figure 5-4 FESEM image of the graphene surface on (a) Al-foil/PET and (b) Al2O3/Al-foil/PET. EDS analysis of (c) graphene/Al-foil/PET and (d) graphene/Al2O3/Al-foil/PET (e) EDS elemental mapping of the graphene/Al2O3/Al-foil/PET presenting C K series, O K series and Al K ser

ies …………………………………………………………….………87Figure 5-5 3D AFM images of (a) 1L-Gr (b) 3L-Gr (c) 5L-Gr on Al foil (d) 1L-Gr (e) 3L-Gr (f) 5L-Gr on Al2O3/Al foil………………….….….89Figure 5-6 Work function of graphene layers on the (a) Al-foil (b) Al2O3/Al-foil substrate by KPFM. Inset showing the surface potential of

graphene layers (1L, 3L and 5L) over Al-foil and Al2O3 substrate (c) energy band diagrams for 1L-Gr, 3L-Gr and 5L-Gr over Al2O3 ……....90Figure 5-7 Schematic illustration of Electronic energy levels of graphene samples and AFM tip without and with electrical contact for three cases: (i) tip and the

1L-Gr (ii) tip and the 3L-Gr and (iii) tip and the 5L-Gr over Al2O3/Al foil/PET……………………………………….…...…………91Figure 5-8 Working mechanism of Gr-TENG with Al2O3 ….….…...…93Figure 5-9 a) ISC and (b) VOC of 1L-, 3L- and 5L-Gr-TENGs without Al2O3 CTL (c) Sheet resistance of graphene as a function of number

of layers ………………………………...…...…………………………….95Figure 5-10 Electrical output of the Gr-TENG with Al2O3 CTL: (a) ISC and (b) VOC of 1L-, 3L- and 5L-Gr. Magnification of the (c) ISC and (d) VOC of the 3L-Gr-TENG with Al2O3 as the CTL. Average mean (e) ISC and (f) VOC generated by pristine Gr-TENGs (1L, 3L

and 5L) and Gr-TENGs (1L, 3L and 5L) with Al2O3 CTL. Error bars indicate standard deviations for 4 sets of data points ……………...…………….….…......96Figure 5-11 (a) CV of Al/Al2O3/3L-Gr/Al at 100 kHz and 1 MHz (b) CV hysteresis of 3L-Gr-TENG with Al2O3 as CTL with different sweeping voltages (c) Surface

charge density of graphene (1L, 3L and 5L)-based TENG with and without Al2O3 as CTL ………………………………...98Figure 5-12 Circuit diagram of output (a) VOC and (b) ISC measurement of 3L-Gr TENG with Al2O3 CTL as a function of different resistors as external loads. Variation in VOC and ISC w.r.t different re

sistors as external loads of (c) 3L-Gr TENG with Al2O3 CTL (d) 3L-Gr TENG without Al2O3 CTL. Relationship between electrical output power and external loading resistance (e) 3L-Gr TENG with Al2O3 CTL (f) 3L-Gr TENG without Al2O3 CTL…………………………………….………………...99Figure 5-13 (a)Electrical stability and du

rability of the 3L-Gr TENG with Al2O3 (b) Schematic illustrations showing the charge-trapping mechanism of 3L-Gr-TENG without and with Al2O3 charge trapping layer ………101Figure 5-14 (a) Photograph showing 20 LEDs being powered (b) Circuit diagram of bridge rectifier (c) Charging curves of capacitors

with various capacitances (d) Photograph of powering a timer …….………………102Figure 6-1 The schematic diagram of the fabrication process for SCG powder based TENG ……………………………………………….….108Figure 6-2 The schematic diagram of the fabrication process for SCG thin-film based TENG via thermal evaporation meth

od ………………109Figure 6-3 FESEM image of (a) SCG powder (inset image illustrates the high magnification of SCG powder) (b) SCG thin-film/Al foil/PET (inset image illustrates the high magnification of SCG thin-film). EDS of the (c) SCG powder (d) SCG thin-film/Al foil/PET…………………………. 112Figure 6-4 Raman

spectra analysis (a) pristine SCG powder (b) SCG thin-film/Al foil/PET. XRD patterns of (c) SCG powder (d) SCG thin film with different thickness ……………………………………… ……….115Figure 6-5 FTIR analysis of the (a) pristine SCG powder sample (b) SCG thin film………………………………………………………………...116Figure 6-6 3D AFM ima

ge of SCG thin-film with various thickness (a) 50 nm (b)100 nm and (c) 200 nm……………………………………...117Figure 6-7 Schematic illustration of working principle of SCG thin-film based TENG …………………………………………………………...119Figure 6-8 Finite element simulation of the generated voltage difference for SCG thin-film b

ased TENG based on the contact and separation between SCG thin film and PTFE …………….……………………….120Figure 6-9 (a) The setup for electrical property testing, which including a Keithley 6514 system electrometer and linear motor. Electrical output (b) ISC (c) VOC of TENGs based on different friction pairs

for checking the triboelectric polarity of SCG…………………………………………...123Figure 6-10 Electrical measurement of (a) ISC and (b) VOC of the SCG thin-film based TENG. Mean value of (d) ISC (e) VOC and (f) Output power density of the pristine SCG powder and thermal deposited SCG thin-film based TENG. ...………

………………………………………125Figure 6-11 (a) Schematic illustration of KPFM for measuring the work function. (b) Surface potential images of SCG thin film with various thickness (50 nm, 100 nm and 200 nm). (c) Surface potential and (d) Work function vs SCG thin film with various thickness (50 nm, 100 nm and 20

0 nm).………….……………………………………………….128Figure 6-12 (a) Isc and (b) Voc of SCG thin film based TENG under different contact frequencies (c) Isc and (d) Voc of SCG thin film based TENG under different separation distance…………………………….129Figure 6-13 Electrical response (a) ISC (b) VOC of pristine SCG powder an

d (c) ISC (d) VOC of SCG thin-film based TENG with respect to different relative humidity (35-85% RH) …………………………….131Figure 6-14 Electrical stability and durability test of the output performance of (a) pristine SCG powder based TENG (b) SCG thin-film based TENG……………………………………………………………132Figure 6-15

Applications of the SCG thin film based TENG as a power supply: (a) Circuit diagram of the bridge-rectifier for charging a capacitor (b) Charging curves of capacitors with various capacitances (0.1, 2.2 and 3.3 µF) (c) Photograph of powering a timer…………………...………133Figure 7-1 Schematic illustration o

f FG based TENG…….….……….139Figure 7-2 Working mechanism of FG based TENG…………………140Figure 7-3 Electrical output of FG-TENG: (a) Isc and (b) Voc …….….141Table captionsTable 2-1 Comparison of flexible G-FETs on/off ratio of our work with other’s work…………………………………………………...………...40Table 3-1 Summary of th

e electrical and mechanical performance of flexible w/o-FG, w/ 1L-FG, w/3L-FG and sandwich FG (FG/PG/FG) samples......................................................................................................52Table 3.2: Comparison of the electrical and mechanical performance of sandwich FG ba

sed F-GFET with previous F-GFET with different gate dielectrics……………………………………………………….………53Table 4-1 Best photovoltaic performance from control and target devices prepared on rigid and flexible substrates……………………………......74Table 5-1 EDS elemental analysis of graphene over Al-foil/PET and Al2O3/Al-foi

l/PET ………………………………………………………88Table 5-2 Comparison of electrical output performance of Gr-TENGs with and without Al2O3 CTL samples used in this study………………103Table 6-1 EDS elemental analysis of SCG-Powder and SCG thin film /Al foil/PET………………………………………………………………...113Table 6-2 Comparison of electrical o

utput performance of SCG-TENGs samples used in this study……………………………………………...126

A La Mode: 120 Recipes in 60 Pairings: Pies, Tarts, Cakes, Crisps, and More Topped With Ice Cream, Gelato, Frozen Custard, and M

為了解決Coffee a la mode 的問題,作者Scarbrough, Mark/ Weinstein, Bruce 這樣論述:

Are you ready to take your baking over the top? Here are sixty decadent and delightful ice creams and the sixty desserts that are their vehicles. A la Mode offers not just solid dessert recipes, from raspberry oat bars to bear claws, from chocolate pecan pie to a white chocolate pavlova, but also

gives you the unforgettable pairings that make these desserts smash hits: apple cranberry pie with Camembert ice cream, chocolate sheet cake with salt caramel frozen custard, and espresso cream jelly roll with mascarpone ice cream.Let's face it: vanilla can sometimes be so... vanilla. A great a-la-

mode pairing should be as decadent as finding the perfect wine to go with your cheese plate. With A la Mode, IACP winners and cookbook dynamos Bruce Weinstein and Mark Scarbrough show you how to create innovative delights such as creamy hazelnut gelato atop coffee-poached pears, or maple frozen cust

ard with a mouthwatering cinnamon roll cake, alongside simpler classics like confetti ice cream with layered vanilla birthday cake. You haven't lived until you've had peanut brittle pie with popcorn ice cream, a Cracker Jack fantasy Because what's a warm pie without ice cream? With A la Mode, you'l

l have to answer that question

高齡日間照顧中心異味樣態調查與新式自然通風效益評估

為了解決Coffee a la mode 的問題,作者吳伊証 這樣論述:

為因應高齡化趨勢,福祉機構的需求不斷增加,而其室內空氣品質的議題近年也受到廣泛關注,然而異味侵擾的現象依然存在於日間照顧中心室內環境中。為要了解日照中心空間使用人員面臨的異味現況,本研究於冬夏兩季使用問卷及電子偵測儀監測調查台灣南部9間日照機構營運時異味發生的樣態,同時也藉由現場調查中異味下降的速度檢測自然通風潛能計算的新概念。綜合考慮問卷與儀器數據,階層式分群法的結果闡明冬夏兩季異味樣態相異。然而,問卷與儀器調查的部分指標在冬夏兩季間出現相反趨勢,問卷中持續時間與每日發生次數為冬季顯著大於夏季多數儀器數據則反之。此外,異味好發的時段並不位於靜或動態時段,而在中午備餐至午休結束,占總機構營運

期間的3成以上。長者口腔異味影響範圍約於24-26cm間;浴廁與中午備餐時藉由自然通風可有效減少42-300cm與37-600cm左右的異味擴散距離。比較考量外氣風向的自然通風手法與異味下降速度,選擇空間面風處與其斜對角的開口所形成的路徑更能有效控制異味的侵擾。異味難以被抑制的主因在於缺乏適切通風計畫,應對不同時間尺度的通風概念需被引入,如何快速並符合經濟效益以降低日照中心室內異味問題須有更多探究。

想知道Coffee a la mode更多一定要看下面主題

Coffee a la mode的網路口碑排行榜

-

#1.Cafe a la mode - 網友評價、菜單| 台北中山區咖啡- 愛食記

店名:Cafe' a' la mode地址:台北市台北市中山北路二段26巷11號... 開啟食記› ... 於 ifoodie.tw -

#2.[台北美食] Cafe a la Mode 中山站小巷美食簡約空間有溫度 ...

陳皮今天無聊在家因為莉芙跑回家不跟陳皮度過週末所以跑去逛了一下中山站來到我的愛店Cafe a la mode 以風水的角度來說這前台有深度會轉賺錢喔(by ... 於 teddy0411.pixnet.net -

#3.[邀約]師大‧Cafe a la mode‧聚餐的好地方!招牌法式布丁吐司好好 ...

cafe à la mode 地址:台北市大安區雲和街2-1號電話:02-2362-3957 營業時間:星期一~五10:00am~10:00pm. 於 beautychu060.pixnet.net -

#4.Café à la Mode - Foursquare

Read 8 tips and reviews from 214 visitors about lively, healthy food and cozy. "Great service!" 於 foursquare.com -

#5.cafe a la mode - [庫嚕網]

首頁 > 各類美食 > 義式料理 > > cafe a la mode. cafe a la mode. 地址. 台北市大安區雲和街2-1號. 電話. 02-2362-3957. 營業時間. -. 公休日. 全年無休. 官網連結 ... 於 www.xizhitang.com.tw -

#6.【捷運台電大樓站】Café à la mode — 一吃就愛上的蛋香法式 ...

而他們的位置是在算師大商圈浦城街的巷弄裡頭,葉子對這邊不太熟,看著地圖走, 才發現原來離羅斯福路還滿近的,而一看到店面時,馬上就有感覺到咖啡館的 ... 於 www.barrelleaf.com -

#7.cafe la mode 招牌法國布丁吐司必點 中山下午茶 - Yulin's Life

中山區可是早午餐以及下午茶的戰區之一呢! 每次選擇都讓Yulin難以抉擇,太多想吃的美食~ 這次選擇cafe la mode,除了有提供早午餐,也有義大利麵燉飯. 於 bassy5292.pixnet.net -

#8.[食記] 中山區Cafe a la mode 好吃又溫馨/捷運中山站 - 窩客島

捷運中山站附近巷弄美食餐廳讓人怎麼試都試不完. 這次跟姊妹聚會選在新光三越南西店後面Cafe a la mode. 其實這間店在師大附近是第一間,店面滿大, ... 於 www.walkerland.com.tw -

#9.a la mode Table - Home - Taipei, Taiwan - Facebook

台北咖啡廳| a la mode Table。肉慾橫流浮誇大盤肉,超大份量疊得就像一座小山高囉!(國父紀念館站) @ 蹦啾♥謝蘿莉La vie heureuse :: 痞客邦:: ... 於 www.facebook.com -

#10.Café à la mode - Pinterest

節省裝置上的空間. 註冊. 儲存. 探索 · Architecture · Commercial And Office Architecture · Commercial Architecture · 咖啡店. Café à la mode Spaces. shinnylee. 於 www.pinterest.cl -

#11.cafe a la mode facebook - 2021 米其林指南餐廳推薦靠北餐廳

cafe a la mode facebook 情報,cafe' a' la mode 可以釋放心中自由無拘無束的能量. 陽光的活力都濃縮在新鮮的食材中,每一口都有千萬好滋味釋,簡單的幸福就從這裡 ... 於 needmorefood.com -

#12.Cafe La Mode

Cafe La Mode is an award winning cafe restaurant in Nicosia, Cyprus with a variety of menu choices. 於 cafelamode.com.cy -

#13.cafe a la mode 名副其實的限量法式布丁吐司! - 小妞的生活旅程

久仰「Cafe' a' la mode」法式布丁吐司盛名,一開始還有點擔心會不會名過於實? 沒想到「Cafe' a' la mode」的法式布丁吐司和餐點都超美味的~一定要跟 ... 於 may1215may.pixnet.net -

#14.台北咖啡廳- 超大份量疊得就像一座小山高囉!(國父紀念館站)

台北咖啡廳| a la mode Table。肉慾橫流浮誇大盤肉,超大. 如果你是肉控那麼肯定要趕快做筆記,大份量肉盤端出來可是讓所有人立馬都傻眼! 於 fairylolita.com -

#15.Bailey's Coffee a la Mode ⋆ Sugar, Spice and Glitter

Brew 2 cups of strong coffee in your favorite method. Measure out 3 oz of Bailey's into each mug. Place 2 scoops of chocolate ice cream in each mug and pour 1 ... 於 sugarspiceandglitter.com -

#16.台灣台北Cafe a La Mode - Trip.com

您可以在Trip.com找到台灣台北Cafe a La Mode 的地址、電話、相片、餐牌及食評等實用資訊。台北市中山區中山北路2段26巷11號. 於 hk.trip.com -

#17.Cafe' a' la mode - LINE熱點

【LINE熱點】Cafe' a' la mode, 咖啡廳, 地址: 台北市中山區中山北路二段26巷11號,電話: 02 2581 6691。全台必吃美食、熱門景點推薦、美食外送、優惠 ... 於 spot.line.me -

#18.Cafe a la mode(中山店) - 菜單價位 - FonFood瘋美食

Cafe a la mode (中山店) (152篇食記) 位於台北市中山區屬於中山南西商圈商圈靠近捷運中山站, 地址:台北市中山區中山北路... 電話:02-2...【台北中山美食|Café à la ... 於 www.fonfood.com -

#19.Cafe a la mode, 台北市中山北路二段26巷11號, Taipei (2022)

cafe' a' la mode, 可以釋放心中自由無拘無束的能量. 陽光的活力都濃縮在新鮮的食材中,每一口都有千萬好滋味釋,簡單的幸福就從這裡開始!! 現金付款,台灣pay. 於 www.restameta.com -

#20.食記 台北大安。古亭站*師大咖啡 阿拉萌得Cafe a la mode ...

這間位在師大附近的Cafe' a' la mode 走的是簡約風格. 雖然在轉角處,但是他的生意還滿不錯的門口有一個小廣場,放了腳踏車,看起來是不是很文青的 ... 於 athena77.com -

#21.餐點好吃,必點熱帶鮮果法式布丁吐司/英式炸魚早午餐/草莓 ...

Cafe a la mode 開了兩間分店,一間在中山,另一間在師大這裡. 師大這間人潮真的是很多,沒有訂位還吃不到下午茶勒. 這裡已經是學生心目中NO.1的早 ... 於 www.jobforum.tw -

#22.師大下午茶"大份量早午餐"法式布丁吐司 - 食omo〃Food×Fun

Cafe a la mode (師大店). 地址:台北市大安區雲和街2-1號 電話:02-23623957 營業時間:一~五10:00~21:30,六日9:30~21:30 10%服務費。提供WIFI。 於 omofood.com -

#23.咖啡館小旅行--捷運中山站--cafe a la mode - 糊里糊塗國的 ...

寫咖啡館小旅行的順序其實跟我去的時間無關耶XD 大概是照心情來寫的啦所以要來介紹稍早一點去捷運中山站買東西時來的這間咖啡店,cafe a la mode 去的 ... 於 katiekao.pixnet.net -

#24.Cafe' a' la mode (中山店) (中山區) - 餐廳/美食評論 ...

Cafe' a' la mode (中山店)(中山區): 讀讀9則則關於Cafe' a' la mode (中山店)客觀公正的美食評論,在Tripadvisor的5分滿分評等中得3分,在中山區的2717家餐廳中排 ... 於 www.tripadvisor.com.tw -

#25.Coffee A La Mode - Moorpark, CA Restaurant | Menu + ...

Order with Seamless to support your local restaurants! View menu and reviews for Coffee A La Mode in Moorpark, plus popular items & reviews. 於 www.seamless.com -

#26.《食記》『Cafe' a' la mode』- 台北市捷運台電大樓站師大夜市

... 結果沒想到起床起得太早一堆店都還沒開阿阿阿!後來尋尋覓覓被我們找到了這家差點唸不出名字的早午餐咖啡店- Cafe' a' la mode,二話不說當然趕快進去吃早餐囉! 於 xnfood.com.tw -

#27.【台北市中山區美食】Cafe' a' la mode - 網友評價 - 飢餓黑熊

Cafe' a' la mode 是一間位於台北市中山區的餐廳,總共有686位網友評價過此餐廳,平均是4.2顆星。 於 ihungrybear.com -

#28.【食記】台北中山Cafe La Mode 歐姆蛋捲配上布丁吐司的悠閒 ...

台北中山Cafe La Mode 歐姆蛋捲配上布丁吐司的悠閒下午茶. 說到下午茶,最先讓人想到的就是東區跟中山站. 這次來到中山站附近尋覓歐姆雷特蛋捲跟布丁 ... 於 alina00.com -

#29.Cafe a la mode 中山店:南京商圈新開幕的設計感好店(義大利麵 ...

Cafe a la mode 中山店(二店)於10/28(周一)正式對外試賣,這幾天店內只接待店家熟客及親朋好友。因為上次在Cafe a la mode師大本店用餐的經驗很好,所以 ... 於 banbi.tw -

#30.【台北市】師大咖啡阿拉萌得【cafe a la mode】

咖啡阿拉萌得用咖啡洗澎澎? 餐廳名稱:cafe a la mode 消費時間:2013年8月地址:台北市大安區雲和街2-1號電話:02-2362-3957 營業時間:週一- 週五: 於 foodhome.pixnet.net -

#31.台北_中山站_Cafe' a' la mode - 黛西Daisy 의놀이카페- 痞客邦

這是一間很不錯的小店. 中山區的環境真的很不錯. 很想住這邊耶~~哈. cafe a la mode中山店. 地址:北市中山區中山北路二段26巷11號(捷運中山站). 電話:2581-6691 ... 於 d934099.pixnet.net -

#32.Coffee A La Mode | The New Yorker

A lady in a self-service grocery store asked the clerk If he had any coffee. He said no, but reached under the counter and slipped half a pound of coffee … 於 www.newyorker.com -

#33.cafe a la mode的文章和評論 - 痞客邦

來看痞客邦超過37 則關於cafe a la mode的文章討論內容: MissHoki 的師大美食.cafe a la mode(師大店).在舒適溫馨的環境好好吃一頓莎莉哈的*台北中山站咖啡館*Cafe ... 於 www.pixnet.net -

#34.【中山下午茶】Cafe a la mode(中山店)~超強大的法式布丁吐司

Cafe a la mode (中山店)位在中山北路的巷子裡,. 離捷運中山站約350公尺,. 逛完新光三越南西店剛好可以去坐坐,. 喝個下午茶悠哉一下! ... 白色為主體的 ... 於 pi73713.pixnet.net -

#35.Coffee A La Mode Menu and Delivery in Moorpark - Uber Eats

Coffee A La Mode ; Cold-Brewed Iced Coffee. GHS 4.35 ; Toasted Bagel - Jalapeno Cheese. GHS 3.50 ; Blended Caramel Vanilla Latte. GHS 6.15 ; Iced Green Tea Matcha ... 於 www.ubereats.com -

#36.台北師大| Cafe' a' la mode 巷弄早午餐 - 披著虎皮的貓

Cafe' a' la mode 師大店facebook: http://www.facebook.com/cafealamode 地址: 台北市大安區雲和街2-1號(地圖) 電話: 02-2362-3957 營業時間: ... 於 rainieis.tw -

#37.Cafe a la mode 搜尋推薦結果 - 輕旅行

[食記] 中山區Cafe a la mode 好吃又溫馨/捷運中山站. Jan 06, 2017 ⁄ 作者:vivi11210. 捷運中山站附近巷弄美食餐廳讓人怎麼試都試不完,這次跟姊妹聚會選在新光三越 ... 於 travel.yam.com -

#38.Caffe a la Mode's – Coffee Shop, Coffee Club

Caffe a la Mode is more than just another coffee shop, or some place to grab a bite to eat. It is a community, crafted to fit the loyal customers of Warwick. We ... 於 caffealamode.com -

#39.Cafe a la mode(師大店)的食記、菜單價位、電話地址

Cafe a la mode (師大店) (110篇食記) 位於台北市屬於師大夜市商圈靠近捷運台電大樓站, 地址:台北市雲和街2... 電話:02-2...【台北中山美食|Café à la mode,推薦 . 於 igotojapan.com -

#40.如果一日餐餐都能吃到早午餐!那到底是該叫什麼餐?四間台北 ...

如果一日餐餐都能吃到早午餐!那到底是該叫什麼餐?四間台北早午餐推薦! cafe Coabana、 Coffee champ、 Cafe a la mode 、TAMED FOX. Watch later. 於 www.youtube.com -

#41.中山「Cafe' a' la mode」.布丁吐司下午茶〃捷運中山站

這次跟著Alina的腳步來到了中山站的”Cafe' a' la mode“. 嘿嘿~雪莉又沒做功課,爽爽跟著來啦!(羞. 下午茶-22.jpg. 突然想到好久沒有出來透氣的阿 ... 於 heidongshelly.com -

#42.[台北]食記。Cafe-a-la-mode簡約空間Brunch & Omelette~捷運 ...

[台北]食記。Cafe-a-la-mode簡約空間Brunch & Omelette~捷運中山站美食 · 最近和老友轉戰捷運中山站附近美食店 · 隱身在安靜的巷弄間 我差點以為走錯路了. 於 drftblog.com -

#43.Cafe' a' la mode是一家位於台北的公司

Cafe' a' la mode 是位于Taipei 的一个咖啡店。 實體的註冊地址為10491台北市中山區中山北路二段26巷11號。 在相應的部分中提供了更詳細的信息。 於 taipeicatalog.com -

#44.[約訪] cafe a la mode - 彩虹泡泡の美食/旅遊/玩樂

【cafe a la mode】下次還要約朋友去吃下午茶^^ 地址: 台北市大安區雲和街2-1號(捷運淡水線至「台電大樓站」3號出口出站,步行約5分鐘) ... 於 perilucky.pixnet.net -

#45.Home | Coffee A La Mode - Moorpark

This process helps us deliver the best whole bean possible to your cup. We are also a premier, locally-owned, specialty coffee and tea house, serving espresso ... 於 coffeealamode1.square.site -

#46.台北中山站咖啡館*Cafe a la mode~有乾燥花的氣氛好餐廳 ...

當時就對他們家的法式布丁土司印象深刻,. 這次突然想起來他們在中山站也有一間分店,. 就訂了這裡的晚餐。 Cafe a la mode中山店在 ... 於 saliha.pixnet.net -

#47.【台北】中山區‧Cafe a la mode義式餐廳(捷運中山站)

這家位於捷運中山站巷弄內的cafe a la mode是之前跟Kathy和Carol相約一起吃飯的餐廳,好久沒見的三個人趁著平日下午休假,相約偷閒的時間, ... 於 www.paine0602.com -

#48.cafe a la mode中山店~讓我超愛的美味燉飯與法式布丁土司

於是我們就有這麼美味又滿意的一餐了。 cafe a la mode位於老爺酒店對面,新葡苑和DAPHNE女鞋中間的巷子,. 其實不算太 ... 於 blog.xuite.net -

#49.[食記] 台北Cafe a la mode 不錯吃的布丁吐司 - 小科科的春天

餐廳名稱:Cafe' a' la mode 消費時間:2019年11月店家地址:台北市中山區中山北路二段26巷11號店家電話:02 2581 6691 營業時間:10:00~21:00(週 ... 於 blog.cti.app -

#50.台電大樓站。cafe a la mode 旅行生活的創意料理。讓人難以 ...

台電大樓站。cafe a la mode 旅行生活的創意料理。讓人難以忘懷銷魂的法式布丁吐司。還有美味的早午餐Brunch跟美式蛋捲. 於 fgblog.fashionguide.com.tw -

#51.食-台北|Cafe' a la mode(師大店)|師大下午茶|店內好吃好拍 ...

食-台北|Cafe' a la mode(師大店)|師大下午茶|店內好吃好拍氣氛相當好|法式布丁吐司系列必點熱帶水果冰茶也好喝~ ... 吃點東西享受午後時光,最近小麥麥 ... 於 maiimage.com -

#52.cafe a la mode限時 :: 台灣咖啡館

姊姊強力推薦的早午餐店【Cafealamode中山店】隱身在中山北路的巷弄裡(台北光點附近),雖然小間,看起來卻十分有情調,不過...週末用餐限時2小時。,Cafealamode是 ... 於 tpecoffee.iwiki.tw -

#53.Cafe a'la mode - Zi 字媒體

Cafe a'la mode 位於中山站附近巷子裡的早午餐。 溫馨小店,簡約安靜,東西好吃,這是我對Cafe a'la mode的評價。 於 zi.media -

#54.《出一張嘴‧台北中山》cafe' a' la mode-中山店 - 個人新聞台

《出一張嘴‧台北中山》cafe' a' la mode-中山店. 推薦 9 收藏 0 轉貼0 訂閱站台. 20190711 W4 1430. 研究所聚餐又一趴,不得不說中山捷運站真的是很好 ... 於 mypaper.pchome.com.tw -

#55.【台北美食】Cafe' a' la mode/捷運中山站附近,讓人驚豔的 ...

【台北美食】Cafe' a' la mode/捷運中山站附近,讓人驚豔的楓糖奶油布丁吐司,不錯喝的冰滴咖啡,值得讓人為其駐足一下午。 · 店名:Cafe' a' la mode. 於 lintzuyang79.pixnet.net -

#56.美食。餐廳 台北中山區中山捷運站Cafe a la mode 中山下 ...

這一天外頭滴滴答答下著大雨,強風吹著,但還是沒有澆熄我跟朋友約會的熱情火, 這間Cafe a la mode位在台北市中山區,搭乘捷運在中山捷運站下車步行 ... 於 livia1028.pixnet.net -

#57.【Cafe a la mode】中山咖啡廳推薦有wifi/插座早午餐很大份 ...

在網路上看到這家cage a la mode好久了,前幾天跟maggie在中山站附近逛街,決定來吃吃看. 說到這家一定很多人想到cafe a la mode師大店 ,不過一店跟 ... 於 47life.tw -

#58.【師大】cafe a la mode - Jan的網路隨記

某天在雲和街發現了這家咖啡店,除了下午茶,還供早午餐、義大利麵,所以約了同事一起前往,正如門口立牌寫的,來個午餐約會吧~ 白色外觀, ... 於 jan098142.pixnet.net -

#59.[台北] cafe a la mode 法式布丁土司 - 好命人- 痞客邦

[台北] cafe a la mode 法式布丁土司 ... 在師大夜市旁邊的巷子裡面,我很少走來這邊的一側, 要不是收到邀請還真不知道有這樣一間店。 白色的牆壁黑色的 ... 於 yonatsumi.pixnet.net -

#60.cafe a la mode_群力永業有限公司 - 104人力銀行

【公司簡介】資本額:250萬元。cafe a la mode, 在這裡盡情去享受著愉快的時光, 心情也輕鬆的飛翔! 人生不就該享受...。公司位於台北市中山區。產業別:餐館業。 於 www.104.com.tw -

#61.[午茶]‧邀約‧台北‧大安‧cafe a la mode‧燉飯、早午餐、法式吐司

久違了師大商圈,之前紛擾不斷的師大, 終於有些好店家還是留下了,這次受到【Cafe a la mode】邀請, 要試一下店裡的人氣商品- 法式布丁吐司, 店家位於雲和街上,臨近 ... 於 justnike.pixnet.net -

#62.【台北食記】Cafe' a' la mode 終於吃到限量法式布丁吐司!捷 ...

早已久仰「Cafe' a' la mode」法式布丁吐司盛名之前還曾跑到師大店去朝聖,無奈因為限量賣完而向隅後來知道在中山站開了二店,離家更近收到邀約讓我好 ... 於 tenjo.tw -

#63.[師大] cafe a la mode,師大巷弄平價cafe - 沒有洋蔥的食記

事情是這樣的,那天跟朋友原本要去吃點點食堂但我們忘記穿點點的東西會有折扣,又剛好經過這家店發現很多人所以就臨時起意決定吃這家了~ 這家店在師 ... 於 h294799.pixnet.net -

#64.地圖: Chien a la mode[食べログ](繁體中文)

店名. Chien a la mode (シアンアラモード). 類型. 咖啡店, 貝果, 西式甜點(其他). 電話・預約. 03-3937-4054 (+81-3-3937-4054). 地址. 東京都練馬區冰川檯2-11-35. 於 tabelog.com -

#65.Coffee A La Mode Delivery Menu - Moorpark - Grubhub

Order delivery or pickup from Coffee A La Mode in Moorpark! View Coffee A La Mode's April 2022 deals and menus. Support your local restaurants with Grubhub! 於 www.grubhub.com -

#66.[台北師大]夢幻黃金鬆軟法式布丁吐司-Cafe a la mode

前些日子看到朋友分享了Cafe a la mode看起來非常誘人的法式布丁吐司,超喜歡吃布丁吐司的我立刻決定北上出差開會開完衝一個下午茶啦!!Cafe a la mode ... 於 angelala.tw -

#67.Cafe a'la mode -台北中山溫馨好吃早午餐,推薦搭配薯餅 ...

Cafe a'la mode 位於中山站附近巷子裡的早午餐。溫馨小店,簡約安靜,東西好吃,這是我對Cafe a'la mode的評價。我還蠻喜歡他們家的薯餅, ... 於 lisajourney.com -

#68.[美食] 中山站cafe a la mode。法式布丁下午茶輕食義大利麵

用心真誠的讓大家能夠享受到健康美味的。 還有讓人念念不忘的法式布丁吐司。 今天就來跟大家分享cafe a la mode的美食吧~. 於 yopalit.pixnet.net -

#69.【Cafe a la mode】師大下午茶~價格親民,餐點好吃,必點 ...

Sep 19. 2016 18:34. 置頂 【Cafe a la mode】師大下午茶~價格親民,餐點好吃,必點熱帶鮮果法式布丁吐司/英式炸魚早午餐/草莓起司蛋糕(師大店) ... 於 gn0930150655.pixnet.net -

#70.心中山|Cafe a la mode 中山店。水準穩定的午餐愛店

捷運中山站一帶,這幾年雨後春筍般竄出許多文靑風、悠閒風的店家,cafe a la mode算是比較早進駐的,N… 於 katefun.wordpress.com -

#71.(中山美食)cafe a la mode(中山店) 敲好吃的法式布丁吐司

中山北路的巷弄裡有不少的咖啡廳cafe a la mode就隱身其中在捷運中山站晃了一陣子,就想找家咖啡廳休息一下歇歇腿不想去太有名的店家(吵鬧的聊天聲會讓 ... 於 ber2563nice.pixnet.net -

#72.A La Mode Cafe and Catering

Sandwiches, Salads, Homemade Soups, ice cream & other desserts with full catering menu in Syracuse, NY. 於 www.alamodecafeandcatering.com -

#73.Cafe a la mode (@cafealamode1) • Instagram photos and ...

65 Followers, 0 Following, 34 Posts - See Instagram photos and videos from Cafe a la mode (@cafealamode1) 於 www.instagram.com -

#74.cafe a la mode 菜單的價格和推薦 - 寵物用品生活推薦指南

2018年10月10日 — 【台北美食】Cafe' a' la mode/捷運中山站附近,讓人驚豔的楓糖奶油布丁吐司,不錯喝的冰滴咖啡,值得讓人為其駐足一下午。 於lintzuyang79.pixnet.net. 於 pet.mediatagtw.com -

#75.【中山站】Cafe a la mode中山店︳恰到好處的美感與舒服 ...

(用餐日期:2018.7/2018.8) 來了兩次「Cafe a la mode」,兩次感覺都蠻好。 第一回和朋友一起來。這店是朋友找的,但我們坐在店裡等著餐點上桌時, ... 於 kklove0620.pixnet.net -

#76.【食記】師大Café à la mode 悠閒自在的咖啡店 - YOYO 愛 ...

【店家資訊】Café à la mode店址:台北市大安區雲和街2-1號電話:02-2362-3957營業時間:AM10:00~PM10:00消費方式:每人低消任一餐飲,需收一成服務 ... 於 vilo92.pixnet.net -

#77.cafe a la mode 師大店, 北歐簡約風格x限量法式布丁吐司

[cafe a la mode] 是位於師大商圈的人氣咖啡館, 販售全日早午餐、義大利麵和燉飯, 還有少見的招牌甜點法式布丁吐司... 靜謐的環境和北歐簡約風格的 ... 於 standinghere.pixnet.net -

#78.中山|Cafe' a' la mode-中山下午茶店推薦!酥脆的法式布丁吐 ...

Cafe' a' la mode 讓人放鬆的中山區下午茶店推薦,服務好、餐點美味! 加了芒果醬的歐姆蛋清爽好滋味,耗時15小時製作的法式布丁吐司外酥內軟, ... 於 shadow810920.pixnet.net -

#79.台電大樓站。cafe a la mode 旅行生活的創意料理。讓人難以 ...

Sep 04. 2013 02:59. 台電大樓站。cafe a la mode 旅行生活的創意料理。讓人難以忘懷銷魂的法式布丁吐司。還有美味的早午餐Brunch及蛋捲. 16832. 創作者介紹. 於 aaweichen.pixnet.net -

#80.【食記】中山Cafe a la mode帶狗狗一起吃好料

最近迷上了寵物友善餐廳,畢竟很多時候太多約會導致沒有時間陪狗狗的我,很希望可以在跟朋友相聚的同時,也陪伴到黑皮♡ ♡ ♡ / 位於中山的Café a la ... 於 www.popdaily.com.tw -

#81.Cafe' a' la mode

Cafe' a' la mode · BRUNCH · PASTA · RISOTTO · SALAD · FRENCH TOAST DESSERT · HOMEMADE DESSERT · ESPRESSO DRINK. 於 qrmn.co -

#82.Cafe a la mode(中山店)啥咪!蛋糕用喝的您喝過沒?中山下午茶 ...

中山捷運站商圈是一個繁忙喧嘩的都市Cafe a la mode遠離塵囂,選擇隔離了好幾條巷弄一條不起眼的小巷子裡一間白色招牌和門面格外引人注目Cafe a la ... 於 www.mobile01.com -

#83.COFFEE À LA MODE - 888 E Los Angeles Ave, Moorpark ...

Delivery & Pickup Options - 161 reviews of Coffee à la Mode "1.) Really nice staff. 2.) REALLY good ice blended 3.) Lots of flavors to choose from 4. 於 www.yelp.com -

#84.台北市「Cafe a la mode(中山店)」複合式咖啡、地址 - 食在北 ...

「Cafe a la mode(中山店)」複合式咖啡商家營業資訊:台北市中山區中山北路二段26巷11號 02-2581-6691,Cafe a la mode (中山店)是一個有捷運中山站、早午餐、法式布丁 ... 於 lovetpe.com -

#85.《吃在台北‧下午茶》捷運中山站:Cafe a la mode (台北中山店)

這家店是朋友帶我來的!聽說它的早午餐很不錯不過我是下午時間來..所以就只有點甜點+飲料下回有機會再來嘗嘗它的早午餐!!! 它有二家店,中山店其實是 ... 於 yumitrip.pixnet.net -

#86.「cafe a la mode menu」懶人包資訊整理 (1) | 蘋果健康咬一口

台北中山站義大利麵餐廳cafealamode (17). 下面是Cafe a la mode的menu,. 提供早午餐、義大利麵、 ..., (用餐日期:2018.7/2018.8) 來了兩次「Cafe a la mode」,兩次 ... 於 1applehealth.com -

#87.[食記] cafe a la mode 中山店- 看板Food - 批踢踢實業坊

餐廳名稱: cafe a la mode 中山店消費時間:2014年/04月地址:台北市中山區中山北路2段26巷11號(中山捷運站) 電話:02-2581-6691 營業 ... 於 www.ptt.cc -

#88.cafe a la mode_群力永業有限公司 - 1111商搜網

cafe a la mode _群力永業有限公司-台北市中山區-咖啡簡餐-(02)25816691-服務業. 於 trade.1111.com.tw -

#89.Café a′la mode - 台北美食 - 台北民宿- 瘋台灣民宿網

收錄台北美食「Café a′la mode」地址、電話與營業時間等完整美食資訊,精彩的網友評論與分享文章,整合鄰近美食 ... Cafe' a' la mode-迎接美好的早晨 ... 於 taipei.fun-taiwan.com -

#90.[食記] 中山區Cafe a la mode 好吃又溫馨/捷運中山站 - Vivi's ...

捷運中山站附近巷弄美食餐廳讓人怎麼試都試不完這次跟姊妹聚會選在新光三越南西店後面Cafe a la mode 其實這間店在師大附近是第一間,店面滿大, ... 於 vivi11210.pixnet.net -

#91.(cafe a la mode)佳慶永業有限公司 - yes123求職網

cafe a la mode 提供早午餐美式蛋捲義大利麵水果鬆餅系列義式咖啡花茶及水果茶系列a la mode 在古法文的詮釋是. 於 www.yes123.com.tw -

#92.食記【台北】中山捷運站Cafe' a' la mode用心美味的下午茶 ...

【Lexie臉消為】中山捷運站附近可以說是下午茶的一級戰區,很多知名的店家都開在那邊今天造訪的Cafe' a' la mode也離中山捷運站很近,步行不到五分鐘 ... 於 lexie.tw -

#93.【咖啡美食】Cafe a la mode,中山站巷弄內的早午餐下午茶 ...

Cafe a la mode ,中山捷運站巷弄內的精緻餐廳剛好與朋友在中山區的小聚餐,隨性就找了這間沒想太多的推門而入~ 就是喜歡這種寬敞的咖啡廳 ... 於 www.fanyafree.com -

#94.[吃] 師大cafe' a' la mode-白色極簡風咖啡廳 - 骰子生活543

今天來吃早午餐師大附近真的好多美美的咖啡廳這次去的是白色極簡風的cafe' a' la mode 中山也有一間分店喔店內隨便一個角落都很美這個位子很有復古風 ... 於 ohdice.pixnet.net -

#95.Cafe a la mode - 網友評價、價錢與訂位地址, 台北市中山區美食

Cafe' a' la mode 捷運中山站附近,讓人驚豔的楓糖奶油布丁吐司,不錯喝的冰滴咖啡,值得讓人為其駐足一下午。 於 35.201.83.62 -

#96.師大美食.cafe a la mode(師大店).在舒適溫馨的環境好好 ...

Cafe' a' la mode 餐點以義大利麵、義式燉飯、早午餐、omelette為主,也提供法式吐司、沙拉、甜點、飲料……等,選擇不少~其中沙拉的食材,均採用小農 ... 於 misshoki.pixnet.net -

#97.[食記]中山。Cafe a la mode - 凌晨三點半

真的超巧的,因為我還在想這周什麼時候去修一下瀏海,簡直是幸運哈哈! 然後我就上網找找中山附近有什麼好吃的囉。 被我發現這一家!Cafe a la mode! 於 rakui0801.blogspot.com -

#98.cafe' a la mode by 商管哲煒 - Prezi

cafe' a la mode. Number of times this content has been viewed 1 Button to like this content ... Cafe' a la mode 創新行銷企劃書. coffee mania. SWOT分析 ... 於 prezi.com